Rota-gravure

is a traditional method of printing that is broadly used in the publishing

industry. In addition, this method is used in many different fields, including

colorful plastic films for food packaging, home appliances, wood-grain printing

for furniture and many more. It was discovered in the 19th century, and works in

a brief manner wherein an engraving of image is transferred onto an image

carrier that is filled with the ink, and then the image is printed on the

substrate with the help of an impression roller.

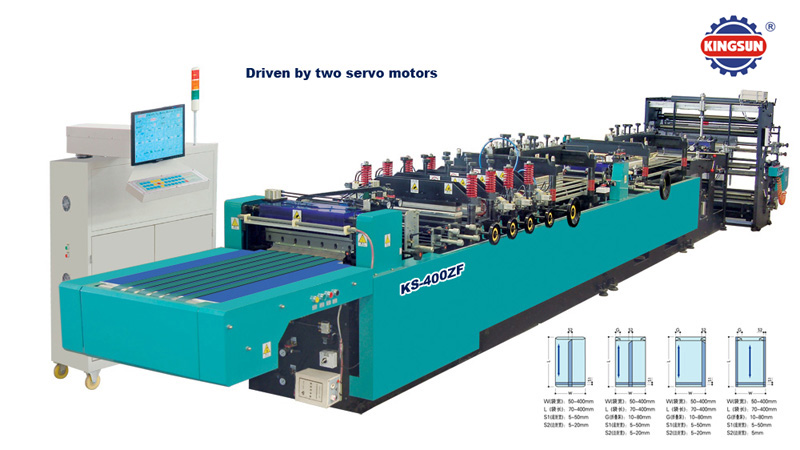

Using

a Rotogravure Printing Press machine,

an image is imprinted on a cylinder as it uses rotary printing press such as

offset printing and flexography. In addition, these roto-printing machines are

best for packing materials, including cellophane, polypropylene bags, roll

paper and polyethylene. Additionally, manufacturers and suppliers of

Rotogravure Printing press from all across the world are providing latest

machines with wide-ranging specifications.

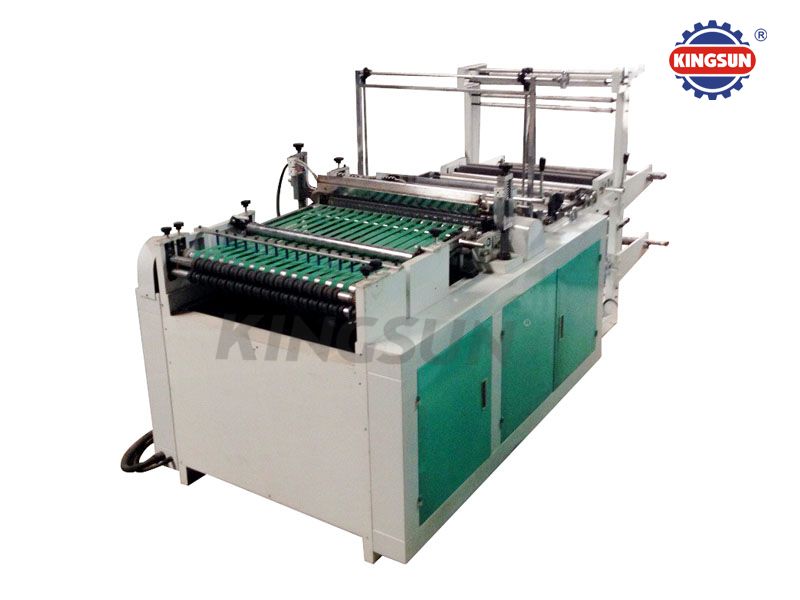

A

rotogravure printer consists copper or of steel plated cylinders, and images

that need to be printed stamp inside it. However, the

surface of the cylinder includes an

utmost number of cells, which transports more ink to the paper. After

that the substrate is pressed between gravure cylinder and impression roller to

get the most wanted results. Now, the image is passed with the help of a dryer

for proper drying method, previous to it passed to the color unit. Rotogravure is one of the high-speed printing

machined that produces the best quality images. The printer is a favored form

of technology that is designed to fulfill the multicolored needs of customers. Besides

printers features front and reversal printing facility and usually related to

the commercial printing of magazines, corrugated boxes, product labels, postcards

and so on.

Today,

the printing is done professionally in the every aspect of print media that

includes magazines, brochures, business cards, newsletters, books and many more.

In addition, all these products are developed by using rotogravure printing machine as this machine provides better

quality results within the quick time. This machine works at its utmost

efficiency and providing qualitative output. Normally, a varied range of

objects includes BOPP (Bi-Oriented Polypropylene) can be

printed on a gravure device. The printer uses oil or water based inks that will

not attach to the non-image areas as well as creates the best images. At the present time, rotogravure printers are getting huge

popularity, particularly in the publishing industry, and most of the companies

and businesses prefer to use this machine to print high-quality images.